Proycotecme, a team of experts in Heat Treatment Furnaces who will work for you.

Tell us what you need and we will advise you on the best solutions.

Mechanical and electrical maintenance team for heat treatment facilities with experience and training.

Technical support

Speed

Incident detection

Processes improvement

Types

· Corrective maintenance: masonry work, insulation, motor repairs, agitator repairs, turbines, …

· Preventive maintenance: correcting small problems before they lead to incidents on a regular basis. Control of consumption, combustion, …

· Predictive maintenance: monitoring of furnace operation.

· Improvement maintenance: retrofitting of furnaces, updating obsolete parts to modernize the heat treatment installation.

Profitability

Advice

Experience

Trust

What should you know before buying an oven?

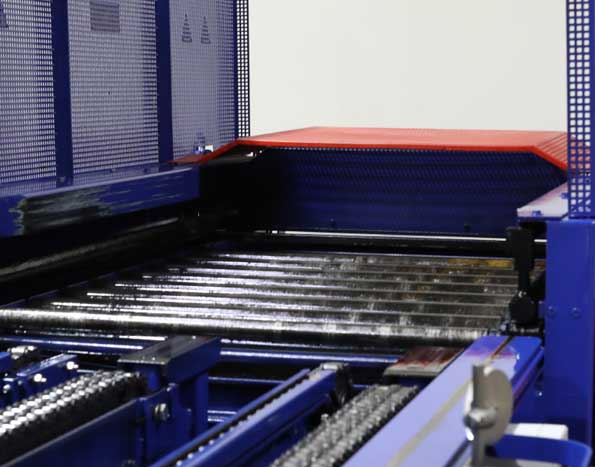

Batch Transfer furnace

Ipsen International partners exclusively for Spain and Portugal. We market, provide after-sales support, technical assistance and maintenance for the entire range of Ipsen controlled atmosphere ovens.

• Batch transfer furnaces

• Grate push-pull transfer furnaces

• Heat treatments with controlled atmosphere; gas cementation, quenching, tempering, annealing, nitriding, carbonitriding, molten salt quenching, nitrocarburizing, …

• Heating: electric or gas

• Fully automated lines

Vertical furnaces and Laboratory

We design and manufacture ovens to suit customer requirements:

• Heat treatments without controlled atmosphere; tempering, annealing, normalizing, drying, curing, pickling …

• Temperature range: from 100C to 1400C

• Heating: electric or gas

• Advanced monitoring and control system

• Process traceability

• Possibility of mobile hearth

Automation and electrical panels

We design and manufacture electrical panels and automation of industrial processes in which temperature is an important factor, adapting to the requirements of each client:

• Line automation and control

• Power and control panels

• Process visualization via PC and/or touch screens

• Panels with modem for online modifications and maintenance

• Temperature and carbon potential control and monitoring

• Data logging: time, data, CO, CO2, C, etc.

• Sound and light alarms

• Panels with thyristors, regulators, programmers, etc.

• Assemblies with PLC, graphic panels, supervision systems, PC, SCADA, etc.

• Panels with built-in gas analyzers

• Reference cabinets and oxygen probe cleaning

Modernization, reform and improvement of ovens

We rebuild, refurbish and modernise industrial ovens, adapting to the requirements of each client and to new safety regulations:

• We modernize complete facilities with new control systems to improve quality

• We reconstruct internal works of ovens

• We move complete facilities

• We transform ovens from electric to gas and vice versa

Complementary equipment

Oiling machines

We design and manufacture oiling machines adapting to the client’s requirements.

• Hot air drying

• Balancing

• Automatic machines connected on-line

Drying machines

We design and manufacture drying machines adapting to the client’s requirements.

• Hot air drying

• Balancing

• Automatic connected on-line

Gas Panels

We design and manufacture gas panels adapted to customer requirements

• For cementation, tempering, carbonitriding, nitriding and nitrocarburizing furnaces

• Equipped with minimum and maximum sensors

• Different types of flowmeters.

• Automated and connected online to improve control and traceability of results.

Methanol Panels

We design and manufacture Methanol Panels adapted to customer requirements

• Stabilization of heat treatment

• Quality improvement in heat treatment

• Automated with alarms and pump changes

• For hardening, tempering, carbonitriding, nitriding and nitrocarburizing furnaces

• Automated and connected online to improve the control and traceability of your products

• High-performance and low-consumption Atex methanol pumps

Loading and unloading carts

We design and manufacture loading and unloading carts adapted to customer requirements.

• Automatic or manual

• Connected online

Spare parts

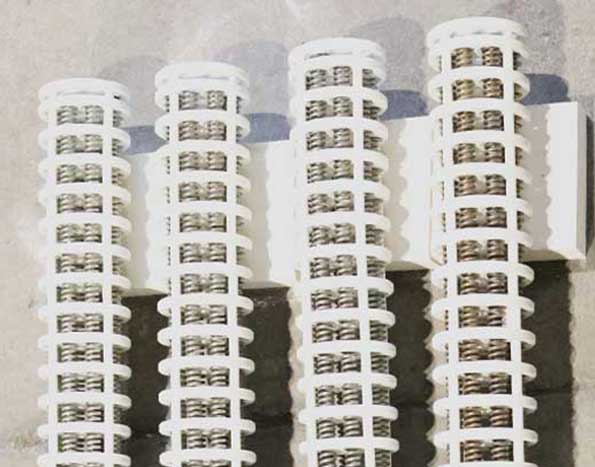

Resistors

We design and manufacture industrial resistors to suit the requirements of each client:

• Resistors for multi-brand furnaces

• Resistors for continuous furnaces, pot furnaces, low and high temperature furnaces, plastic injection furnaces…

• Ceramic resistors (mullite and corderite) made with NiCr and FeAl wires. Wide range of qualities depending on the temperature and working power

• Graphite resistors

• Submerged resistors for tempering baths

• Resistors embedded in ceramic blocks

Radiant tubes

We design, manufacture and market radiant tubes for furnaces to suit the requirements of each client:

• Radiant tubes for electric and gas furnaces

• Metallic radiant tubes; mechanically welded or centrifugal casting

• Ceramic radiant tubes with alumina base (mullite), silicon carbide (SiC), nitrided silicon carbide (NSiC) or reaction-bonded silicon carbide (RBSiC)

• Most common qualities in mechanically welded stainless steel and refractory: Aisi 310s (Din 1.4845), Alloy 330 (Din 1.4886), Incoloy DS (Din 1.4862), Incoloy 601 (Din 2.4851) and Avesta 253 MA (Din 1.4835)

• Most common qualities in casting: Aisi 310s (Din 1.4845) and Din 2.4879

Muffle

We design, manufacture and market muffles for continuous and rotary furnaces, adapting to the requirements of each Customer:

• Silicon Carbide (CSi) transfer furnace muffles

• Mechanically welded metal muffles for continuous furnaces in different grades of stainless and refractory steel: Aisi 310s (Din 1.4845), Alloy 330 (Din 1.4886), Incoloy DS (Din 1.4862), Incoloy 601 (Din 2.4851) and Avesta 253 MA (Din 1.4835)

• Muffles for rotary furnaces for casting + welding in stainless and refractory grades: Aisi 310s (Din 1.4845) and Din 2.4879

Crucibles

We design, manufacture and market crucibles for vertical, pot and bell furnaces, adapting to the requirements of each client:

• Mechanically welded metal crucibles in different grades of steel Refractory: Aisi 310s (Din 1.4845), Alloy 330 (Din 1.4886), Incoloy DS (Din 1.4862), Incoloy 601 (Din 2.4851) and Avesta 253 MA (Din 1.4835)

• Ceramic crucibles: in silicon carbide (SiC), mullite and alumina

Turbines, propellers and fans

We design, manufacture and market turbines, propellers and fans for multi-brand furnaces, adapting to the requirements of each client:

• Machine-welded metal turbines in different qualities of refractory steel: Aisi 310s (Din 1.4845), Alloy 330 (Din 1.4886), alloy 800 HT (Din 1.487 … 1.4862), Incoloy 601 (Din 2.4851) and Avesta 253 MA (Din 1.4835)

• Turbines made of refractory cast iron with high resistance to temperature and stress

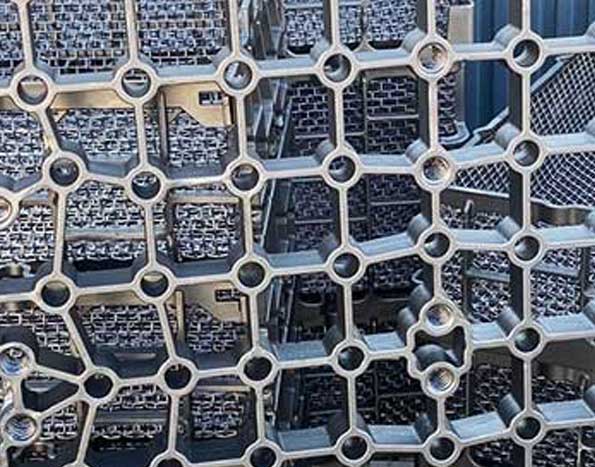

Chains, conveyor belts and meshes

We design, manufacture and market chains, conveyor belts and meshes to suit the requirements of each client:

• Machine-welded chains for drag furnaces in stainless steel and refractory quality: Aisi 310s (Din 1.4845), Alloy 330 (Din 1.4886) and Incoloy DS (Din 1.4862)

• Chains with cast links in stainless steel and refractory quality: 37/18 (Din 1.4865), 35Ni25Cr (Alloy 800HT), Din 1.4886, 35Ni25Cr (Alloy 800HT) and 35Ni25Cr (Alloy 800HT). 2.4879

• Woven wire mesh for continuous annealing, tempering, welding furnaces, etc. in different sizes according to the client

Stackable-baskets, baskets and containers

We design, manufacture and market baskets, baskets and containers for furnaces, adapting to the requirements of each client:

• Round rod + wire mesh mechanically welded baskets for transfer or vertical furnaces

• Remountable foundry baskets for transfer or vertical furnaces

• Most common qualities mechanically welded in stainless steel and refractory: Aisi 310s (Din 1.4845), Alloy 330 (Din 1.4886), Incoloy DS (Din 1.4862), Incoloy 601 (Din 2.4851) and Avesta 253 MA (Din 1.4835)

• Most common qualities in foundry … 1.4845), Din 1.4849, Din 1.4865, 48/79, and Din 2.4879

Grids, trays and casting tools

We design, manufacture and market grids, trays and casting tools for furnaces, adapting to the requirements of each client:

• Casting grids for transfer and batch furnaces

• Casting rollers for transfer furnaces and special applications

• Most common qualities in casting: Aisi 310s (Din 1.4845), Din 1.4849, Din 1.4865, 48/79, and Din 2.4879

Insulating materials

We have a large warehouse of refractory insulation materials for the thermal insulation of furnaces:

• Fibers in blanket and in bulk

• Rolls of refractory and biosoluble blanket

• Blanket blocks refractory folded

• Anchors and washers in stainless steel and refractory

• Rigid plates: refractory ceramic fiber and calcium silicate

• Ceramic strips and bands: ceramic fiber and fiberglass

• Square and round gasket in ceramic fiber and glass

• Custom prefabricated gaskets